Fracture and Structural Integrity: The Podcast

Stay at the cutting edge of fracture mechanics and structural integrity research with the official podcast of the Fracture and Structural Integrity journal. Join us for insightful interviews with top researchers, in-depth discussions of groundbreaking papers, and explorations of emerging trends in the field.

RSS Spotify YouTube Amazon Music

Papers published in 2023-2024 on F&SI focused on Additive Manufactured Materials

2025-01-29

Additive Manufactured Materials: a deep dive focused on the papers published in Fracture and Structural integrity in 2023-2024

More DownloadFiletype: MP3 - Size: 21 MB - Duration: 17:36m (160 kbps 24000 Hz)

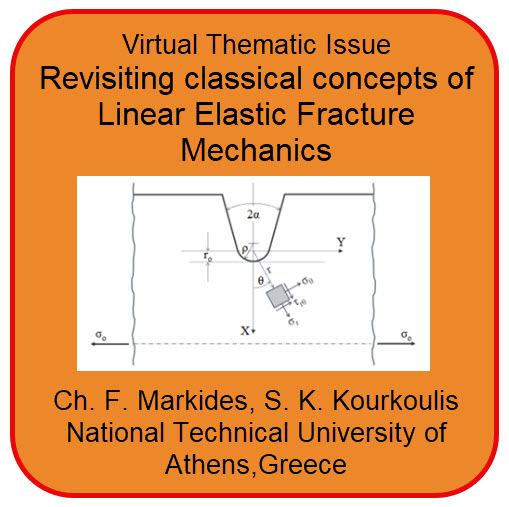

Revisiting classical concepts of Linear Elastic Fracture Mechanics

2024-12-27

The audio explores fracture mechanics, stress intensity factors, and contact stresses, emphasizing damage tolerance and material properties.

More DownloadFiletype: MP3 - Size: 40 MB - Duration: 33:56m (160 kbps 24000 Hz)

ESIAM23: an interview with Jan Torgersen

2024-12-27

The interview with Yan Torgersen highlights the advantages of additive manufacturing in the energy sector

More DownloadFiletype: MP3 - Size: 2 MB - Duration: 1:29m (192 kbps 48000 Hz)

ESIAM23: an interview with Nima Razavi

2024-12-27

The interview with Nima Razavi discusses the importance of structural integrity in additive manufacturing, emphasizing the need for predictive tools.

More DownloadFiletype: MP3 - Size: 3 MB - Duration: 2:12m (192 kbps 48000 Hz)

ESIAM23: an interview with Liviu Marsavina

2024-12-27

The interview with Livio Marsavina highlights the importance of additive manufacturing and structural integrity.

More DownloadFiletype: MP3 - Size: 2 MB - Duration: 1:27m (192 kbps 48000 Hz)

ESIAM23: an interview with Abilio De Jesus

2024-12-27

he interview discusses the importance of a specialized additive manufacturing conference focused on structural integrity. ESIAM23, considered a success, is expected to continue in the coming years

More DownloadFiletype: MP3 - Size: 2 MB - Duration: 1:33m (192 kbps 48000 Hz)

ESIAM23: an interview with Sara Bagherifard

2024-12-27

The interview with Sarah Bagherifard discusses the importance of customizable solutions and the mixing of materials in additive manufacturing.

More DownloadFiletype: MP3 - Size: 2 MB - Duration: 1:36m (192 kbps 48000 Hz)

Powered by Podcast Generator, an open source podcast publishing solution | Theme based on Bootstrap